A Bottom-Up Approach to Nanocrystalline Graphene at the Water-Air Interface

December 2, 2025 – Researchers from Leiden University (Netherlands), Ulm University (Germany), TU Eindhoven (Netherlands), and TU Dresden (Germany) have developed a novel bottom-up synthesis method for centimeter-sized nanocrystalline graphene monolayers by pyrolyzing a Langmuir monolayer of polyaromatic hydrocarbons at the water-air interface. The resulting material has a thickness of just 0.36 nm—comparable to single-layer graphene—and offers a modular strategy for designing nanocrystalline 2D films with potential applications in nanoelectronics and as free-standing membranes.

Carbon materials find use in a wide range of applications, including adsorption and membrane separation of gases and ions, [1] energy storage devices, [2] and chemical sensors. [3] These materials are usually prepared by pyrolysis of organic precursors. The engineering of bulk carbon materials is achieved through modulation of precursors' structure and stacking mode, [1] alongside optimization of pyrolysis conditions. [4] However, for 2D carbon materials such as graphene, amorphous carbon monolayer, and nanocrystalline graphene, the resulting film morphology is regulated mainly by pyrolysis conditions—for instance, temperature, [5] pressure, [6] and flow rates. [7] Although many carbon precursors, such as methane, ethanol, and benzene, have been used for 2D carbon materials growth, modulation of the 2D carbon materials obtained by pyrolysis through the molecular structure of carbon precursors has remained challenging because these processes use simple and volatile molecules, and the amount of carbon on the substrate cannot be controlled by the chemical structure of carbon precursors. Recent theoretical and experimental studies demonstrate that by reducing the grain size down to a few nanometers, nanocrystalline graphene/amorphous carbon monolayer with a large number of grain boundaries exhibits distinct electronic properties, [8,9] making it an interesting material for fundamental research and technical applications. For instance, nanocrystalline graphene-MoS2 van der Waals (vdW) heterostructures show current rectified behaviors.

Research on approaches to obtain nanocrystalline graphene monolayers with a certain degree of control over internal monolayer morphology would benefit from a modular approach to structure these monolayers from the bottom-up. During the CVD growth of nanocrystalline graphene, the high concentration of active carbon species provides high nucleation density, and therefore the growth of multilayers, with an overall film thickness of more than a few nanometers. [10] Remarkably, by quenching a high temperature Pt foil in ethanol or by laser-assisted CVD growth on Cu substrate with carbon precursors, [5,9] well defined nanocrystalline graphene has been obtained. So far, self-assembled monolayers of aromatic thiols have proven very efficient in synthesizing amorphous carbon films. [8,11,12] Recently, the research team demonstrated the synthesis of a molecularly thin amorphous carbon monolayer (with a thickness of 2 nm) by pyrolyzing the Langmuir monolayer of amphiphilic hexa(2,2'-dipyridylamino)hexabenzocoronene polyaromatic hydrocarbon (PAH). [13,14] The carbon source for the amorphous carbon monolayer is provided by a non-volatile, highly thermally stable PAH monolayer. The PAHs adopt an edge-on orientation on the surface of water and later on the substrate due to the π-π stacking effect and hydrogen bonds between water and the pyridine groups of the PAHs.

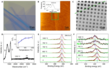

The centimeter-sized nanocrystalline graphene monolayer was prepared by pyrolyzing the Langmuir monolayer of hexa(terpyridine)hexaphenylbenzene (HTPHPB) monomer (Fig. 1A-B) under an inert atmosphere. The monomer HTPHPB was synthesized following a literature procedure. [15,16] A chloroform solution of HTPHPB (1 mg/mL) was spread on the water surface in a Langmuir-Blodgett trough. After full evaporation of the chloroform (30 min after depositing HTPHPB solution), the barrier was closed slowly at a speed of 1 mm/min until the desired surface pressure (15 mN/mm) was reached. The mean molecule area (MMA) obtained from the isotherm curve is about 244 Ų, which is close to the size of HTPHPB calculated from its single crystal structure, indicating that the monomers adopted a face-on configuration on the water surface.

The behavior of the HTPHPB molecules on the water surface was further explored through molecular dynamics (MD) simulations. A water slab was considered with different amounts of HTPHPB molecules adsorbed on both water surfaces. These MD simulations highlight the predominant role of the hydrogen bonds (H-bonds) between the water molecules and the HTPHPB in guiding the arrangement at the interface. This contrasts with a previous study on the water-hexa(2,2'-dipyridylamino)hexabenzocoronene (HPAHBC) interface, [13] where competition was observed between π-π intermolecular stacking interactions between large coronene cores and hydrogen bond interactions of the molecules on the water surface. A single HTPHPB molecule isolated on the water surface leads to an average of 9 hydrogen bonds (Fig. 1D, black curve). The molecule lies nearly flat on the water surface with a tilt angle of ~13° (Fig. 1E, black curve, and Fig. 1F).

When considering five HTPHPB molecules randomly distributed on the water surface, the simulations show that the molecules lie essentially parallel to the water surface with an average of 7 hydrogen bonds (Fig. 1D, red curve) and a tilt angle of ~15.5° (Fig. 1E, red curve, and Fig. 1G). The small difference in hydrogen bond number between the single-molecule and five-molecule cases can be explained by the presence of more pyridine interactions. On average, the thickness of the five-molecule cluster is around 9.5 Å, in good agreement with the experimental value after Langmuir-Blodgett compression (7 Å). The researchers noted a central X-shape core of interaction that strengthened and stabilized the cluster symmetrically, which might represent the seed of nanocrystal graphene formation (Fig. 1G). The average distance between pyridines in dimer or trimer groups is ~3.6 Å with either parallel-sandwich, antiparallel-sandwich, parallel-displaced, antiparallel-displaced, or T-shaped configurations. [17]

Calculations at the Density Functional Tight Binding (DFTB) level with D3BJ dispersion correction on the five HTPHPB molecules cluster and one HTPHPB molecule were performed. Based on these calculations, the estimated π-π stacking interaction energy per interacting pyridine is around –3.30 kcal mol⁻¹, which is in good accordance with the literature. [17] The hydrogen bond energy between pyridine and water is about 3.70 kcal mol⁻¹, which is comparable to the π-π stacking energy between pyridines. [18] The pyridine-stacking of five molecules leads to a reduction of approximately two hydrogen bonds per HTPHPB molecule, corresponding to a total energy loss of around 37 kcal mol⁻¹. However, the π-π stacking between 42 interacting pyridines within five molecules produces an energy gain of –138.47 kcal mol⁻¹, thereby stabilizing the HTPHPB molecules in a planar pyridine-stacked configuration at the interface with water (Fig. 1G).

Subsequently, the Langmuir monolayer was transferred onto a Si wafer by vertical deposition. The HTPHPB monolayer before annealing remained intact without cracks and could be free-standing, probably due to the interactions between pyridines from adjacent HTPHPB monomers. Before the transfer, the Si wafer was treated with O₂ plasma (200 W) for 1 min to form a hydrophilic surface. The Si wafer with HTPHPB monolayer on top was then annealed for 15 min in vacuum (1 mBar, Ar atmosphere). The nanocrystalline graphene monolayer on Si/SiO₂ wafer gives similar contrast as monolayer graphene (Fig. 1H, Fig. 2A). The thickness of the nanocrystalline graphene monolayer measures 0.36 nm with an average roughness (Ra) of 0.07 nm (Fig. 2B), sharing the same thickness as single-layer graphene and thinner than an amorphous carbon monolayer, [5] indicating the atomic thin nature of the nanocrystalline graphene. The SEM image of the nanocrystalline graphene on the Quantifoil grid shows that the monolayer has good mechanical strength and can be free-standing over at least 2 μm openings (Fig. 2C).

The annealing temperature needs to be sufficiently high to trigger the rearrangement of carbon atoms. Raman spectroscopy was carried out to explore the annealing process of the membrane under different temperatures. Due to the lack of large-scale conjugation, the HTPHPB monolayer exhibits no Raman signal. After annealing above 700 °C, intense D and G peaks were observed, corresponding to the bond stretching of sp³-hybridized defects and sp²-bonded pairs. [19] Notably, only weak 2D peaks can be found, demonstrating the lack of long-range order even up to 1000 °C (Fig. 2D). Since samples annealed below 700 °C did not give rise to D and G peaks, the researchers conclude that the conjugation structure first emerged at ca. 700 °C, which is in perfect agreement with the transition temperature determined by X-ray photoelectron spectroscopies. The intensity ratio between the D and G peaks (ID/IG) increased from c.a. 1.61 at 800 °C to 2.27 at 1000 °C (Fig. 2D, insert), indicating an average defect distance LD of around 1.5 nm. [20,21]

The annealing process at different temperatures was further investigated using XPS. Before annealing, the C 1s XPS spectrum of HTPHPB can be described by two main components, corresponding to sp² carbon at 284.6 eV and C-N at 285.7 eV (Fig. 2E). The N 1s XPS spectrum of the HTPHPB monomer exhibits a main peak at 398.9 eV, which is assigned to pyridinic nitrogen atoms (Fig. 2F). With increasing annealing temperature (up to 1000 °C), the C 1s spectrum changes only slightly and is then dominated by sp² carbon.

Despite thorough spectroscopic characterizations providing macroscopic information, the local structure of the annealed monolayers remained elusive. Therefore, the research team further explored the atomic structure using AC-HRTEM. Selected-area electron diffraction exhibits two rings at 4.7 nm⁻¹ and 8.1 nm⁻¹, coinciding with graphitic carbon. The diffusive nature of the diffraction rings demonstrates the lack of long-range order, which is in agreement with Raman spectroscopy. Fig 3A presents a typical AC-HRTEM image of the nanocrystalline graphene monolayer annealed at 1000 °C compared with CVD graphene (Fig. 3F). Due to the chromatic and spherical aberration corrections, the instrumental resolution is down to 80 pm when operating at 80 kV. Therefore, the carbon atoms can be unambiguously resolved, allowing for straightforward structural determination.

However, due to the disordered atomic arrangement, quantitative structural analysis—including bond lengths and angles, and the occurrence frequency of polygons—is not a trivial task. Therefore, the researchers developed a neural network based on U-net architecture to automatically determine atomic positions in AC-HRTEM images. [22] By determining the position of every single atom, the distribution of bond length and angle, and polygon percentage can be extracted statistically. For instance, Fig. 3B illustrates the polygon mapping based on this algorithm. To enhance the accuracy of the statistical analysis, the team incorporated segmentations into the neural network, such that non-monolayer regions induced by surface contamination and local thickness variation are excluded.

By evaluating 34 experimental AC-HRTEM images with 29 nm × 29 nm field-of-view, the researchers found that nanocrystalline graphene (Figs. 3C-3D) exhibits a substantial broadening of the bond length and angle distributions as compared to chemical vapor deposited (CVD) graphene (Figs. 3F-3G) and their bond length and angle distributions (Figs. 3H-3I). The full width at half maximum (FWHM) of the bond angle distribution increased from 16.3° (CVD graphene) to 24.0° (nanocrystalline graphene). Additionally, the FWHM of the bond length distribution peak broadened from 0.27 Å (CVD) to 0.39 Å (nanocrystalline), whereas the peaks remain centered at 120° and 1.4 Å, manifesting the presence of sp² carbon with short-range order. Fig. 3E demonstrates the statistics of polygon frequency derived by real-space mapping. When comparing with the statistics of CVD graphene (Fig. 3J), the team observed a substantial increase in pentagons at the cost of hexagons, whereas the percentage of heptagons increased only slightly.

As the annealing temperature increased, a higher fraction of monolayer regions (sp²) was observed, and the grain size measures around 2 nm—a similar phenomenon was observed in experiments involving in situ annealing of nanocrystalline graphene in TEM. Although annealing above 700 °C could already fully decompose the pyridine motifs and trigger atomic rearrangement, the remaining carbon atoms from the HTPHPB molecules first adopt a highly disordered configuration at the early stage, serving as an ultrathin carbon reservoir. Further energy transfer via heating drives the carbon atoms into an energetically favorable crystalline state, leading to the formation of nanocrystalline graphene monolayers.

As the nanocrystalline graphene monolayer is prepared on an insulating substrate (Si wafer), it is possible to measure the resistance directly (Fig. 4A). Unlike graphene, which shows high electron mobility and low resistance, the nanocrystalline graphene monolayers prepared at 750 degrees and 1000 degrees are insulators (Figs. 4B-4C). The current under 200 mV is below 1 pA and noisy. The resistance value exceeds 10 TΩ sq⁻¹, representing the highest number reported so far among 2D carbon membranes. [5,9] This non-conductive structure, compared to the monolayer amorphous carbon films and nanocrystalline graphene reported in the literature, [5,23] is likely attributable to the inert Si wafer substrate used during preparation, where a high density of defects cannot be effectively repaired during high-temperature growth.

The nanocrystalline graphene prepared at 1000 °C shows slightly better structural stability upon laser exposure. The etching process results from thermal oxidation and sublimation. [24] The stability difference between nanocrystalline graphene and pristine graphene can be attributed to the abundance of grain boundaries and small grain size, which largely decreases thermal conductivity. [25]

Resource: Xue Liu, Dario Calvani, Christopher Leist, Max Makurat, Adéla Melcrová, Meng He, Douwe Scholma, G. J. Agur Sevink, Francesco Buda, Yannick Hermans, Jan P. Hofmann, Haoyuan Qi, Xinliang Feng, Wouter H. Roos, Ute Kaiser & Grégory F. Schneider (2025). Monolayer nanocrystalline graphene synthesized from pyrolyzing a Langmuir monolayer of a polyaromatic hydrocarbon. Science Advances 11, eadt3424. DOI: 10.1126/sciadv.adt3424

Zhou, S. et al. (2024). Adsorption mechanism of CO₂/CH₄ in kaolinite clay: insight from molecular simulation. Energy Fuels 33, 6542-6551. https://doi.org/10.1021/acs.energyfuels.9b00539

Liu, R. et al. (2015). A bottom-up synthesis of nitrogen-doped porous carbon for supercapacitors. Carbon 81, 620-628. https://doi.org/10.1016/j.carbon.2014.10.001

Wang, X. et al. (2018). A novel humidity sensor based on honeycomb-like porous carbon derived from bio-waste. Sens. Actuators B Chem. 260, 1098-1105. https://doi.org/10.1016/j.snb.2018.01.114

Wang, Q., Yan, J., Wang, Y., Wei, T., Zhang, M., Jing, X. & Fan, Z. (2014). Three-dimensional flower-like and hierarchical porous carbon materials as high-rate performance electrodes for supercapacitors. Carbon 67, 119-127. https://doi.org/10.1016/j.carbon.2013.09.070

Toh, C. T. et al. (2020). Synthesis and properties of free-standing monolayer amorphous carbon. Nature 577, 199-203. https://doi.org/10.1038/s41586-019-1871-2

Dong, J. et al. (2023). Ultrathin nanocrystalline/amorphous carbon films with tailored sp³/sp² bonding grown by physical vapor deposition. Carbon 213, 118292. https://doi.org/10.1016/j.carbon.2023.118292

Zhou, Y., Loh, K. P. & Lin, J. (2018). Synthesis of graphene from acetylene via chemical vapor deposition: Growth mechanism and effects of hydrogen and carrier gas. Carbon 126, 165-175. https://doi.org/10.1016/j.carbon.2017.10.022

Turchanin, A. & Golzhauser, A. (2012). Carbon nanomembranes from self-assembled monolayers: functional surfaces without bulk. Prog. Surf. Sci. 87, 108-162. https://doi.org/10.1016/j.progsurf.2012.05.001

Hong, J.-Y. et al. (2021). Monolayer nanocrystalline graphene from a liquid precursor. Nanoscale 13, 12677-12687. https://doi.org/10.1039/D1NR02689J

Lee, J.-H. et al. (2014). Wafer-scale growth of single-crystal monolayer graphene on reusable hydrogen-terminated germanium. Science 344, 286-289. https://doi.org/10.1126/science.1252268

Nottbohm, C. T. et al. (2011). Novel carbon nanosheets as support for ultrahigh-resolution structural analysis of nanoparticles. Ultramicroscopy 111, 417-422. https://doi.org/10.1016/j.ultramic.2010.12.010

He, M., Guo, X. & Qi, H. (2023). Shaping 2D materials by radiation. Nat. Rev. Phys. 5, 662-681. https://doi.org/10.1038/s42254-023-00649-x

Liu, X. et al. (2022). Pyrolysis of a Langmuir monolayer to molecularly thin amorphous carbon. Nanoscale 14, 13070-13079. https://doi.org/10.1039/D2NR03206H

Liu, X. et al. (2023). In situ visualization of pore evolution in monolayer amorphous carbon membranes. 2D Mater. 10, 011001. https://doi.org/10.1088/2053-1583/aca666

Gu, Y. et al. (2016). Flexible electronic eardrum. Nano Res. 10, 2683-2691. https://doi.org/10.1007/s12274-017-1470-1

Schlütter, F. et al. (2014). π-Conjugated heterotriangulene macrocycles by solution and surface-supported synthesis toward honeycomb networks. J. Am. Chem. Soc. 136, 8946-8953. https://doi.org/10.1021/ja502910y

Tsuzuki, S., Honda, K., Uchimaru, T. & Mikami, M. (2005). Ab initio calculations of structures and interaction energies of toluene dimers including CCSD(T) level electron correlation correction. J. Chem. Phys. 122, 144323. https://doi.org/10.1063/1.1876092

Malaspina, T., Coutinho, K. & Canuto, S. (2002). Ab initio calculation of hydrogen bonds in liquids: A sequential Monte Carlo quantum mechanics study of pyridine in water. J. Chem. Phys. 117, 1692-1699. https://doi.org/10.1063/1.1485963

Ma, Z. et al. (2015). Sulfur-doped graphene derived from cycled lithium–sulfur batteries as a metal-free electrocatalyst for the oxygen reduction reaction. Angew. Chem. Int. Ed. 54, 1888-1892. https://doi.org/10.1002/anie.201410258

Lucchese, M. M. et al. (2010). Quantifying ion-induced defects and Raman relaxation length in graphene. Carbon 48, 1592-1597. https://doi.org/10.1016/j.carbon.2009.12.057

Araujo, P. T., Terrones, M. & Dresselhaus, M. S. (2012). Defects and impurities in graphene-like materials. Mater. Today 15, 98-109. https://doi.org/10.1016/S1369-7021(12)70045-7

Leist, C., He, M., Liu, X., Kaiser, U. & Qi, H. (2022). Deep-learning pipeline for statistical quantification of amorphous two-dimensional materials. ACS Nano 16, 20488-20496. https://doi.org/10.1021/acsnano.2c06807

Tian, H. et al. (2023). Disorder-tuned conductivity in amorphous monolayer carbon. Nature 615, 56-61. https://doi.org/10.1038/s41586-022-05617-w

Lin, L. et al. (2018). Optothermoplasmonic nanolithography for on-demand patterning of 2D materials. Adv. Funct. Mater. 28, 1803990. https://doi.org/10.1002/adfm.201803990

Liu, H. K., Lin, Y. & Luo, S. N. (2014). Grain boundary energy and grain size dependences of thermal conductivity of polycrystalline graphene. J. Phys. Chem. C 118, 24797-24802. https://doi.org/10.1021/jp508035b