SALVE III Schedule

SALVE was started on January, 1st 2009. It is composed of the sub-projects SALVE I, SALVE II and SALVE III. SALVE I ended on December, 31st 2010. Within the frame of this project, the partners Ulm University, Zeiss Microscopy and CEOS GmbH evaluated the prerequisites for low-voltage electron microscopy imaging, spectroscopy and sample preparation. These feasibility studies for the development of the SALVE II TEM consisted of adjusting and/or newly developing components of a Libra 200 Cs-corrected TEM for optimum high resolution operation in the range between 20-120 kV and of developing the novel CS/CC-corrector for these low voltages. The SALVE I TEM, which was a Cs-corrected Libra 200 TEM optimized for operation at 20 kV was operational since July 2010 [see here]. For more details, see reference [1].

Before the development of the SALVE II microscope (project phase SALVE-II) could be started, the prospects of success were evaluated by the Scientific Advisory Board, the DFG and the MWK Baden-Württemberg by means of the results of the feasibility study. After approval, the setup of the SALVE II instrument started right after the end of SALVE I; but after withdrawal from the TEM market, Carl Zeiss company stepped out of the SALVE project in 2013 [see here].

Nevertheless, research on sample preparation [2-4], theory and imaging [5-7] for low-voltage aberration corrected TEM at Ulm University and the improvement of the CS/CC-corrector for low voltages at CEOS GmbH was continued.

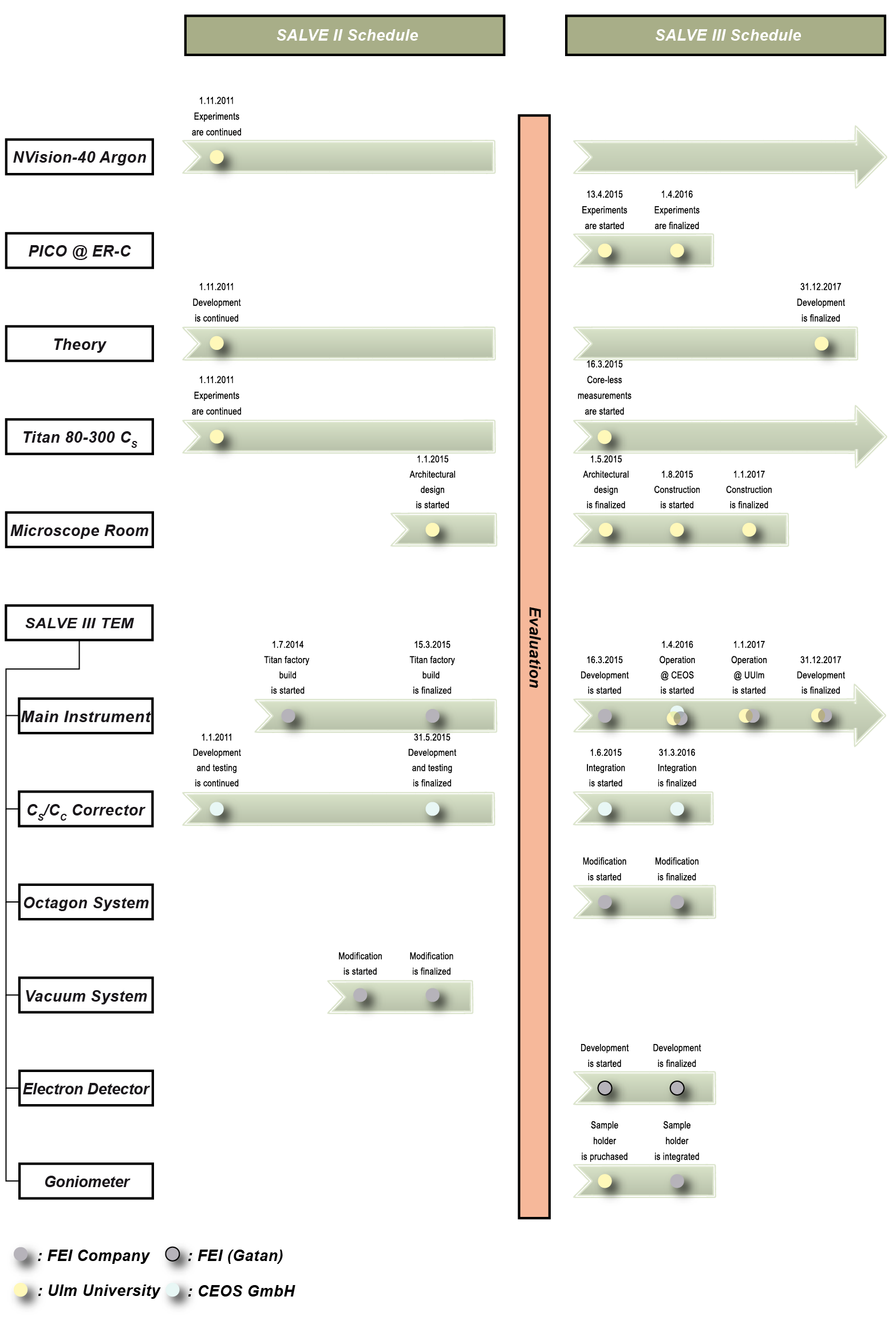

In 2014, Ulm University, FEI Company and CEOS decided to apply for the continuation of the project with FEI as TEM manufacturer replacing Zeiss. The proposed SALVE III project was evaluated by the Scientific Advisory Board, the DFG and the MWK Baden-Württemberg and approved to start on March, 16th 2015.

The SALVE III project concerns itself with all four fundamental aspects of microscopy: the instrument itself, TEM sample preparation, experimentation: imaging, spectroscopy and in-situ microscopy, and theory: elastic and inelastic imaging theory at low voltages. Thus it connects high-end microscopy with frontier applications and state-of-the-art theory on materials properties.

With the achieved experience in the development of a low-noise sample carrier and the newly developed commercial FEI-MEMS holder, we plan also to advance in-situ microscopy at low voltages. This includes the new highly stable liquid-nitrogen holder, by the company Fishione. The possibility to work at liquid-nitrogen temperature is a fundamental prerequisite for many experiments planned within the frame of the project.

From 9/2014-12/2015 main experiments will be performed at University of Ulm (FEI Titan 80-300), selected experiment will be carried out in Julich in cooperation with Rafal Dunin-Borkowski (PICO, CS/CC-corrected instrument at 50 kV). Starting from 4/2016, experiments will be performed on the new SALVE III microscope.

In agreement of simulation and experiments conducted in SALVE I-II, the contrast is fundamentally limited by Johnsen noise [8]. With our current CS/CC aberration corrector we expected focus-spread-limited contrast of 32% and 45% and focus-and-image-spread-limited contrast of 14.7% and 14% for 80 and 20 kV respectively. CEOS will be working on pushing the image spread limitations further by improving the path of rays in the corrector. Simultaneously, all other noises must be pushed to their limits as well, especially those from the basic microscope column and from the room environment.

Cooperation with other groups (summed up as the SALVE science team) will be continued during SALVE III. Also, the SALVE science team will comprise many new partners.

- Kaiser, U., Biskupek, J., Meyer, J. C., Leschner, J., Lechner, L., Rose, H., Stöger-Pollach, M., Khlobystov, A. N., Hartel, P., Müller, H., Haider, M., Eyhusen, S., & Benner, G. (2011). Transmission electron microscopy at 20kV for imaging and spectroscopy. Ultramicroscopy, 111: 1239-1246, doi: 10.1016/j.ultramic.2011.03.012

- Lechner, L., Biskupek, J., & Kaiser, U. (2012). Improved Focused Ion Beam Target Preparation of (S) TEM Specimen—A Method for Obtaining Ultrathin Lamellae. Microscopy and Microanalysis: 18: 379-384, doi: 10.1017/S1431927611012499

- van Mierlo, W., Geiger, D., Robins, A., Stumpf, M., Ray, M. L., Fischione, P., & Kaiser, U. (2014). Practical aspects of the use of the X 2 holder for HRTEM-quality TEM sample preparation by FIB. Ultramicroscopy, 147: 149-155, doi: 10.1016/j.ultramic.2014.08.007

- Algara-Siller, G., Lehtinen, O., Turchanin, A., & Kaiser, U. (2014). Dry-cleaning of graphene. Applied Physics Letters, 104, 153115. doi: 10.1063/1.4871997

- Lee, Z., Meyer, J. C., Rose, H., & Kaiser, U. (2012), Optimum HRTEM image contrast at 20 kV and 80 kV - Exemplified by graphene. Ultramicroscopy, 112: 39-46, doi: 10.1016/j.ultramic.2011.10.009

- Lee, Z., Rose, H., Hambach, R., Wachsmuth, P., & Kaiser, U. (2013), The influence of inelastic scattering on EFTEM images-exemplified at 20 kV for graphene and silicon. Ultramicroscopy, In Press, doi: 10.1016/j.ultramic.2013.05.020

- Lee, Z., Rose, H., Lehtinen, O., Biskupek, J., & Kaiser, U. (2014). Electron dose dependence of signal-to-noise ratio, atom contrast and resolution in transmission electron microscope images. Ultramicroscopy, 145, 3–12. doi: 10.1016/j.ultramic.2014.01.010

- Uhlemann, S., Müller, H., Hartel, P., Zach, J., & Haider, M. (2013). Thermal magnetic field noise limits resolution in transmission electron microscopy. Physical Review Letters, 111: 046101, doi: 10.1103/PhysRevLett.111.046101